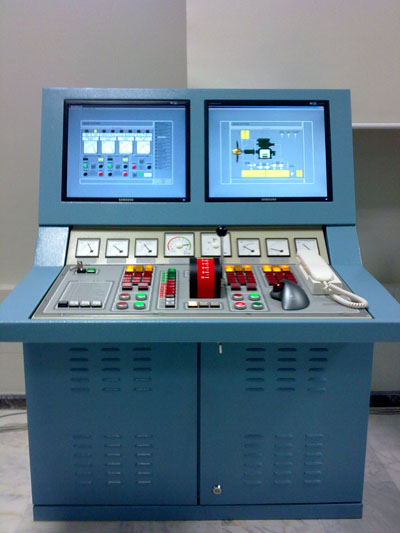

Engine Room Simulator

GEMISIM, is the representative of UniTest Machine Simulator in Turkey. UNITEST is the world leader in marine training software and engine room simulators. All UNITEST products comply with the International Convention on Seafarers' Training, Documentation and Watchkeeping Standards.

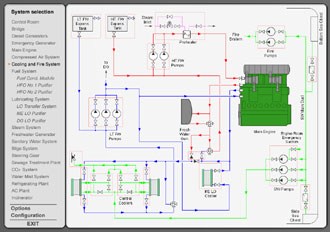

The Ship Machine Simulator offers all the features mentioned in the following items simulated in the computer environment.

Meets the requirements specified in the STCW 95 contract. Basic Machine Room Operations for Students, Emergency Operations, Fault Reduction, Fuel Economy and Energy Exchange Trainings.

All UNITEST products have received a certificate of conformity with the provisions of the International Convention on Documentation and Watchkeeping Standards from November 2014 - STCW 2010 Convention (with Manila Amendments), ( STCW Certificate 2018 (STCW_2018.pdf, 2 271 KB). This document was issued by the Shipping Poland Register.

Engine Room Features

Planning of operation processes and programs,

Analysis of machine performance.

Supervision and control functions.

Detection of faults.

Maintaining safe machine shift.

Main and auxiliary machine and combined control system operations.

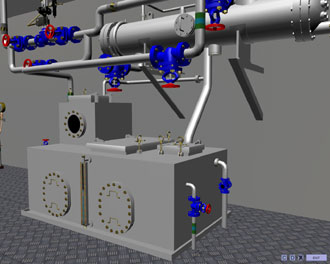

Pump systems and combined control system operations.

Alternator, generator and control system operations.

Safety and emergency procedures. 1.2.9. Pollution prevention.

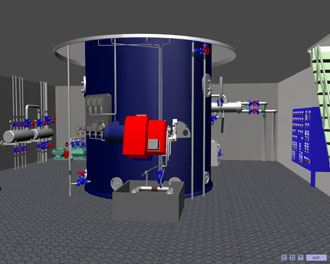

Main Engine

- - Fixed propeller and remote control system

- - Can maneuver with diesel and fuel oil

- - Two-stroke, low speed and can work backwards.

Ship Power Unit

- - Two medium speed diesel generators

- - Four stroke, medium speed fixed direction

- - Has a shaft generator.

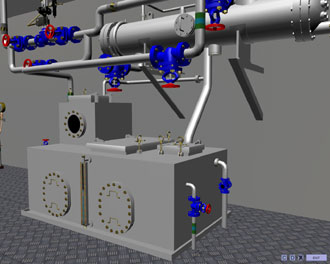

Fuel Systems

- - It has diesel, fuel-oil fuel storage feature and can be delivered to the Main Engine, Generators and Auxiliary Steam Boiler.

- - Fueloil and diesel storage tanks

- - Resting tanks

- - It will be a flow tank

- - Sludge Pump

- - Fuel separators

- - Fueloil and diesel service tanks

- - Mixer box

- - Fuel supply pump

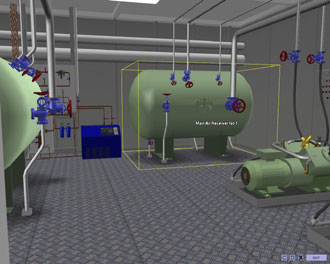

Cooling Systems

- - Can be divided into two subsystems as fresh water cooling and sea water cooling.

- - Sea water central cooling

- - Fresh water tower is low and high temperature cooling.

Lubrication Systems

- - Lubricating oil storage tank

- - Transmission to main engine and generators

- - Lubricating oil separator

Air Compressor Systems

- - Water-cooled piston air compressors

- - Two main starting systems and a separate DG starting system

- - Control air system

Bilge and Balancing Systems

- - Hold bilges and engine room bilges

- - Level alarms in all bilges

- - Bilge pumps

- - Bilge oily water separator

- - Many balance tanks and valves

- - Circuit diagram system and pump

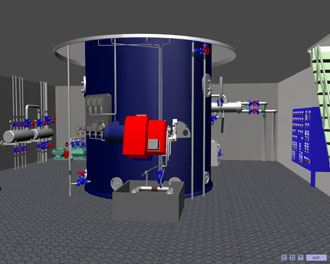

Steam Systems

- - Steam will be produced by the auxiliary boiler.

- - Steam will be used for heating fuel and water.

- - Highly heated steam for turbo generators will be produced in the flue boiler.

Power Supply

- - Two medium speed four-stroke diesel generators

- - Remote controlled

Cooling and Air Conditioning Systems

- - Cooling System compressor (R22) gas

- - Compressor water cooled

- - Air Conditioning System suitable for the comfort of personnel and passengers

- - Inlet and outlet fans

Steering Gear and Fire Extinguishing Systems

- - Two different hydraulic system equipment

- - Fire extinguishing system, fire pump and independent emergency fire pump

Additional Systems

- - Start, shutdown, freeze and mixing features in the simulator software control system

- - Scenario selection, loading, start and finish features

- - Quick information about the engine room can be accessed

- - Environmental information can be entered.

- - Faults can be introduced

- - Monitoring function

- - Summary record keeping feature

- - Alarm information

- - Operation monitoring values

- - Start test, standby and finish tests

- - Bridge control functions

- - Telegram commands can be sent

- - Remote control of rudder pumps

Checklist Supports

- All engine operation checklists can be prepared.

Training software

- - Tank levels, pressure levels, operating source

- - Simulator can be frozen

- - Faults can be introduced.

- - Telegraph commands can be sent.

- - System alarms can be seen.

- - Machine speed can be seen.